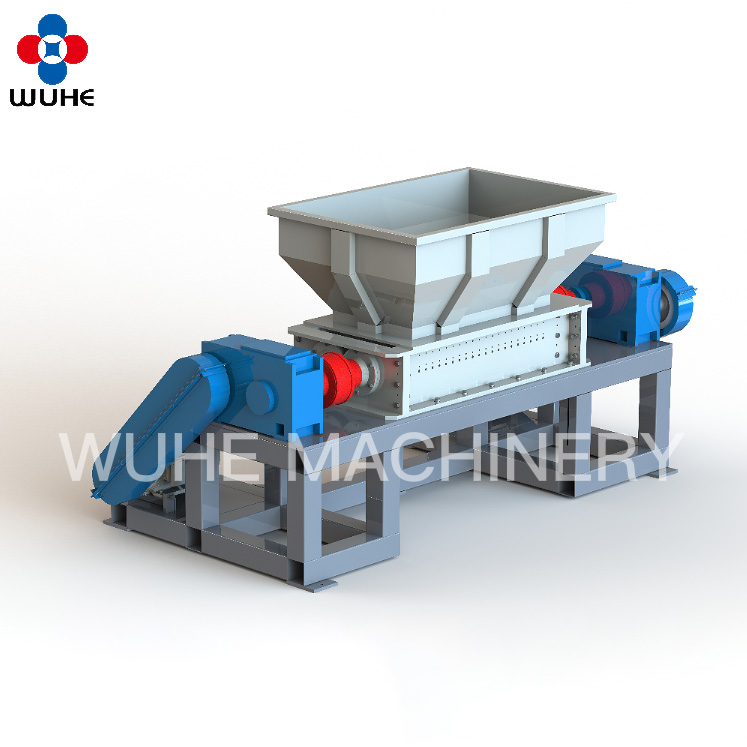

BPS Pipe shredder machine unit

Specification

|

Model |

BPS-800 |

BPS-1000 |

BPS-1450 |

|

Motor power(Kw) |

45Kw*2 |

55Kw*2 |

75Kw*2 |

|

Rotating speed(rpm) |

38 |

32 |

21 |

|

Rotor diameter(mm) |

850 |

1050 |

1500 |

|

Rotor width(mm) |

800 |

1000 |

1500 |

|

Rotary blade |

76 |

95 |

145 |

|

Fixed blade |

5 |

5 |

5 |

|

Hydraulic power(Kw) |

5.5 |

7.5 |

7.5 |

|

Biggest pipe(mm) |

Ф630*3000/Ф630*6000 |

Ф800*3000/Ф800*6000 |

Ф1200*3000/Ф1200*6000 |

| Feeding box

|

● Closed material box ● Hydraulic opening ● Door bolt insurance |

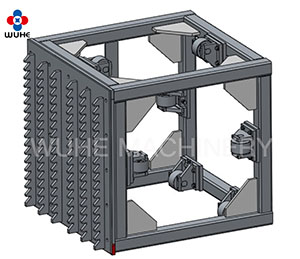

| Shredder chamber

|

● Modular design and high strength of the box ● CNC processing ● Heat treatment processing ● Box: 45 # steel |

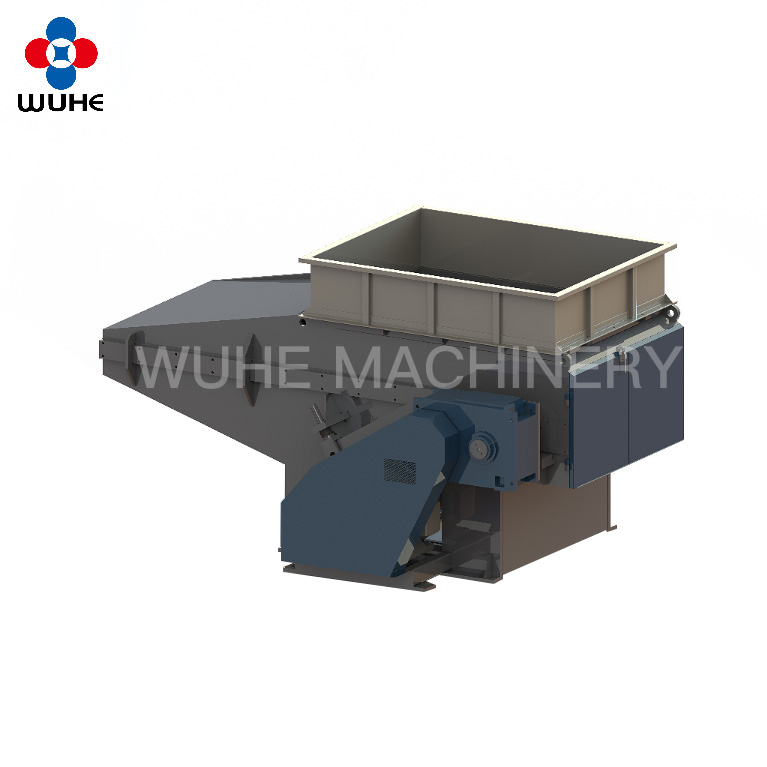

| Pusher trolley

|

● Modular mobile roller ● CNC processing ● Roller bottom surface and side support guide ● Bottom sealing of the pushing box ● Effectively prevent material leakage ● Hydraulic propulsion, two-stage oil cylinder |

| Rotor

|

● Blade high-precision optimized layout ● High efficiency shredding, large shear force, low load ● Overall tempering and tempering heat treatment ● CNC processing ● Blade material: Cr12MoV, twice used ● Cutterbed imported from Italy |

| Rotor bearing | ● High strength, high safety factor bearings ● CNC machining ensures accuracy ● External bearing seat, effective dust prevention |

| Drive

|

● Hard tooth surface reducer ● Elastomer efficient shock absorption device to protect the reducer and power system ● SPB belt drive |

| Hydraulic system | ● Pressure and flow regulation ● Water cooling to prevent overheating of the hydraulic system oil temperature ● System pressure: 3-10Mpa |

| Control system | ● PLC automatic control system |

Write your message here and send it to us