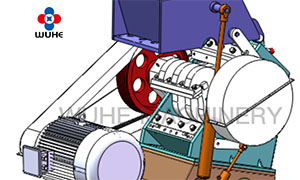

GSP series pipe crusher

Main parameter

|

Model |

Power (KW) |

Rpm (R/MIN) |

Max Pipe D (MM) |

|

GSP-500 |

22-37 |

430 |

Ф250 |

|

GSP-700 |

37-55 |

410 |

Ф400 |

| Feeding hopper | ● Special designed feeding hopper to avoid material splashing. ● Satisfy special requirement to make sure the feeding continuity |

Rack |

● Special shape design, high strength, easy maintenance ● The fixed knife fixing structure optimization ● The quenching and tempering, stress relief heat treatment ● CNC process ● Rack opening method: hydraulic ● Body material: 16Mn |

| Rotator

|

● The blades are in lean arrangement ● The blades distanc 0.5mm ● High quality steel welding ● The quenching and tempering, stress relief heat treatment ● CNC process ● Dynamic balance calibration ● Blades material: SKD-11 |

| Rotor bearing | ● Embedded bearing pedestal, to prevent the dust going into the bearing ● CNC process ● High precision, stable operation |

| Mesh | ● Consists of mesh and mesh tray ● The mesh size should be designed according to different material ● CNC process ● Mesh material: 16Mn ● Mesh opening method: hydraulic |

| Drive | ● SBP belt high efficient drive ● High torque, hard surface gearbox |

| Hydraulic system | ● Pressure, flow adjustment ● System pressure: >15Mpa |

| Suction device | ● Stainless steel silo ● Powder recycling bag |

Write your message here and send it to us