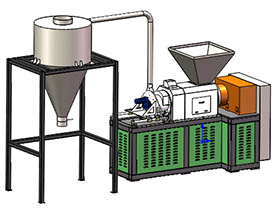

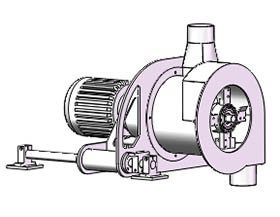

Recently, we tested our new product: PP/PE films woven bags and nylon materials Squeezing compactor dryer squeezer. This is the order of our Russian customer. It will be sent to the customer soon.

The plasticizing effect of this machine is very good, and there is no requirement for the water content of raw materials, so we can use it in the plastic recycling washing production line of plastic film, bags, or woven materials. It can be connected with floating washer directly, While drying and dewatering, we can also carry out the pre-plasticizing treatment of materials, which will be more effective for the next step of plastic material recycling into particles.

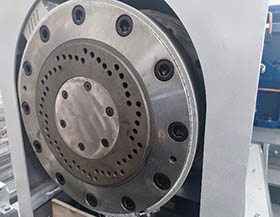

The Squeezing compactor equipment adopts screw extrusion principle, then discharge the water out from the materials. It will has a strong friction in the processing of extrusion. The materials will heated after friction, then the materials will in a semi plasticizing state. After the cutting system, the materials will transported to the silo by air sending, The materials can be easy packed under the silo or processing it to granules again.

If you used Squeezing compactor, this machine can instead of following three machines. Dewatering machine, dryer and a Agglomerator. High efficiency and low consumption is also it’s features.

A. Suitable raw material: PE, HDPE, LDPE,PP films or woven scraps/ nylon

Material thickness: ≤0.5mm

Total capacity: 600-700 kg/h

B. Condition:

● Indoor, No dangerous part for the voltage, Temperature 0-40℃

● Voltage: Customized

C. Specification:

|

Item |

Technical parameter |

QTY |

|

Squeezing compactor

|

Capacity:about 600-700kg/h

|

1 set |

|

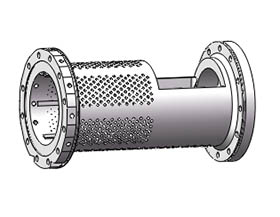

Barrel

|

Material: 38CrMoAl Nitriding treatment.CNC processing

|

|

|

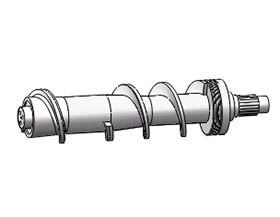

Screw

|

Screw diameter:300mmMaterial: 38CrMoAl Nitriding treatment.CNC processin

|

|

|

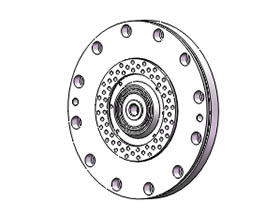

Mold

|

Material: 38CrMoAl Nitriding treatmentCNC processing

|

|

|

Cutting system

|

Cutting hopper: stainless steelQuantity of cutting blades: 4pcsMaterial of blades: SKD-11Cutting angle: 30°

|

|

|

Drive |

Hard surface reducerSPC belt high efficient driveBelt quantity: 6 roots |

|

|

Air sending silo

|

Material: stainless steelFan motor power: 5.5kw

|

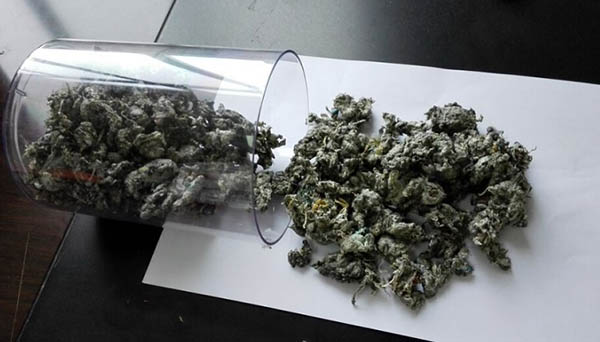

PP material after squeezing

PA material after squeezing

PE material after squeezing

Post time: Apr-26-2023