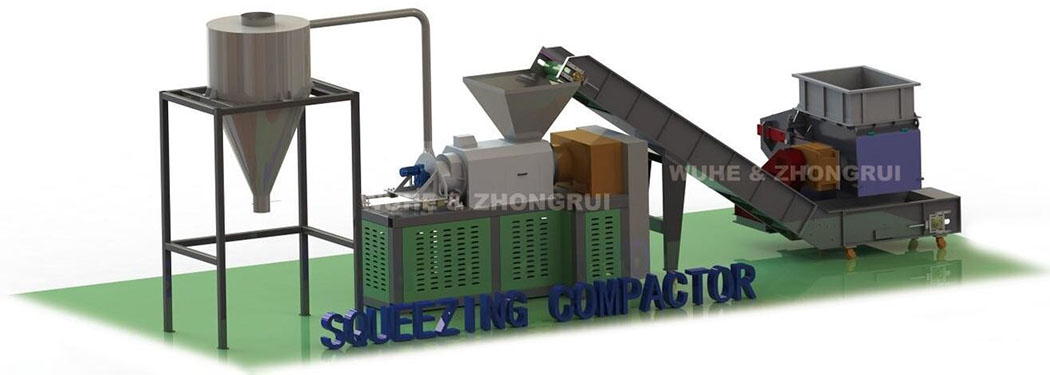

Recently, we tested our new product: PP/PE films woven bags and nylon materials Squeezing compactor dryer squeezer. This is the order of our Russian customer. It will be sent to the customer soon.

The Squeezing compactor is suitable for washed films/bags, PP woven bags, nylon fiber materials and so on. There is no requirement for the moisture, this Squeezing compactor machine can connecting with floating washer directly.

The Squeezing compactor equipment adopts screw extrusion principle, then discharge the water out from the materials. It will has a strong friction in the processing of extrusion. The materials will heated after friction, then the materials will in a semi plasticizing state. After the cutting system, the materials will transported to the silo by air sending, The materials can be easy packed under the silo or processing it to granules again.

If you used Squeezing compactor, this machine can instead of following three machines. Dewatering machine, dryer and a Agglomerator. High efficiency and low consumption is also it's features.

Suitable raw material: PE, HDPE, LDPE, PP nylon (films, bags )or woven bag, non-woven cloth, fiber.

Material thickness: ≤0.5mm

Capacity range: 300-600kg/h, it is customized

Main parameter:

|

Belt conveyor

|

● Function: rubber belt conveying the materials to the next process |

|

Squeezing compactor machine

|

● Applicable materials: washed or cleand PE, HDPE, LDPE, PP nylon (films, bags )or woven bag, non-woven cloth, fiber capacity: 300-600kg/h ● Products humidity: 3-8% |

|

Barrel

|

● Material: 38CrMoAl Nitriding treatment ● CNC processing |

|

Screw

|

● Material: 38CrMoAl Nitriding treatment ● CNC processing |

|

Template

|

● Material: 38CrMoAl Nitriding treatment ● CNC processing |

|

Compactor device

|

● Material: 38CrMoAl ● CNC processing |

|

Cutting system

|

● Cutting hopper: stainless steel ● Quantity of cutting blades: 4pcs/set ● Material of blades: SKD-11 |

|

Drive

|

● Hard surface reducer ● SPC belt high efficient drive |

|

Electrical control system

|

● PLC automatic control |

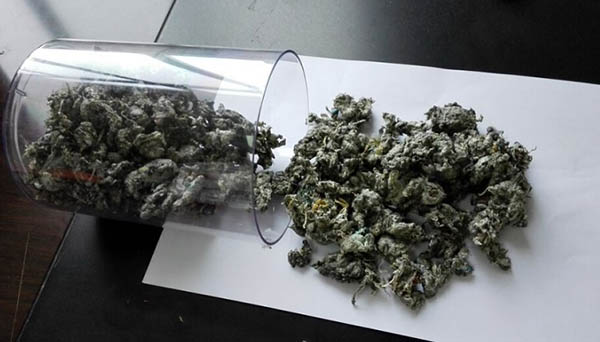

PP material after squeezing

PA material after squeezing

PE material after squeezing

Post time: Sep-15-2022