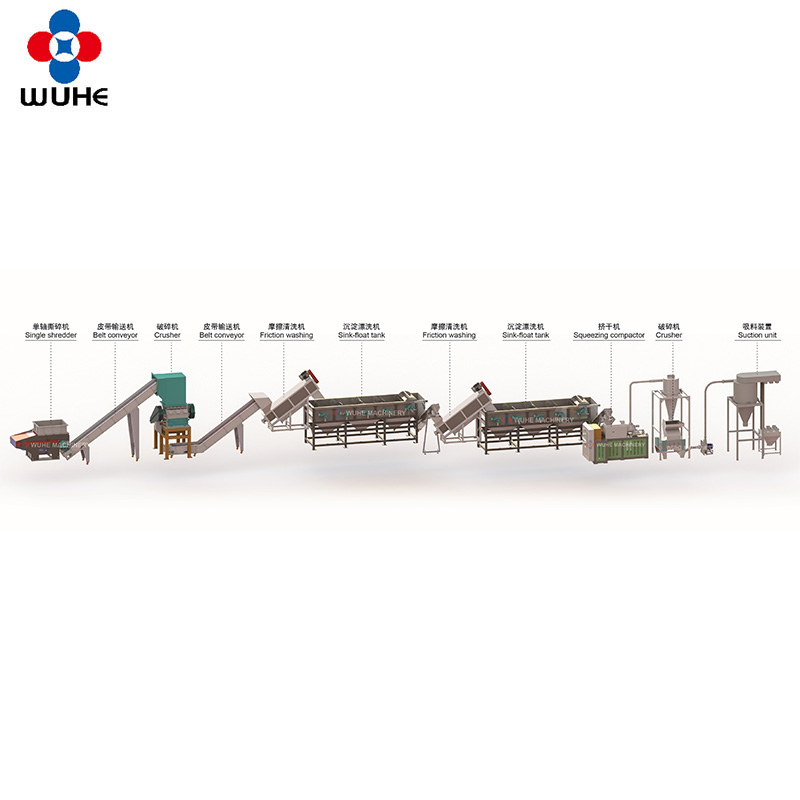

PE,PP film washing production line (high efficient squeezer compactor machine)

Main parameter

Belt conveyor

● Function: rubber belt conveying the materials to the next process.

Shredder machine

● Function: Shredded films or bags can be small to 20mm-50mm according to different needs.

Crusher machine

● This machine is designed just for breaking plastic film and bags, which adopts strong rip shear to break plastic film. The body of the machine is welded with good steel plate, and the base adopts channel steel to weld the frame structure, which is firm and reliable. And the outsourcing is wrapped with sealing plate to form a closed structure for safety.

High speed friction washer machine

● WH series high-speed friction washer is widely for washing recycled waste plastic, especially for plastic bottles, sheets and film, etc.

● Part in contact with materials in high-speed friction washer is made of stainless steel, stainless and no pollution to the washed materials. Full automatic design needs no adjustment during operation.

● Principle: Separated spiral screw keeps flakes from going out immediately but rotating on a high-speed basis. Therefore mutual strong frictions between flakes and flakes, flakes and screw can separate flakes from dirty things. The dirty will be discharged from sieve holes.

Screw loader machine

● Function: using screw conveying the materials to the next process.

Floating washer machine

●WH series floating washer tank is washing and separate PE films&PP woven bags from the dust materials.

●The machine is made up of frame, washing tank, stirring tool and conveying system.

●Washing tank: made of stainless steel, the wall board contacted with water is made of stainless steel.

●Stirring tool: made of stainless steel to convey and wash material, it is used to scatter the material, and enlarge the contact surface of material and water, and push forward the material and put the material under the water and has the immerge effect.

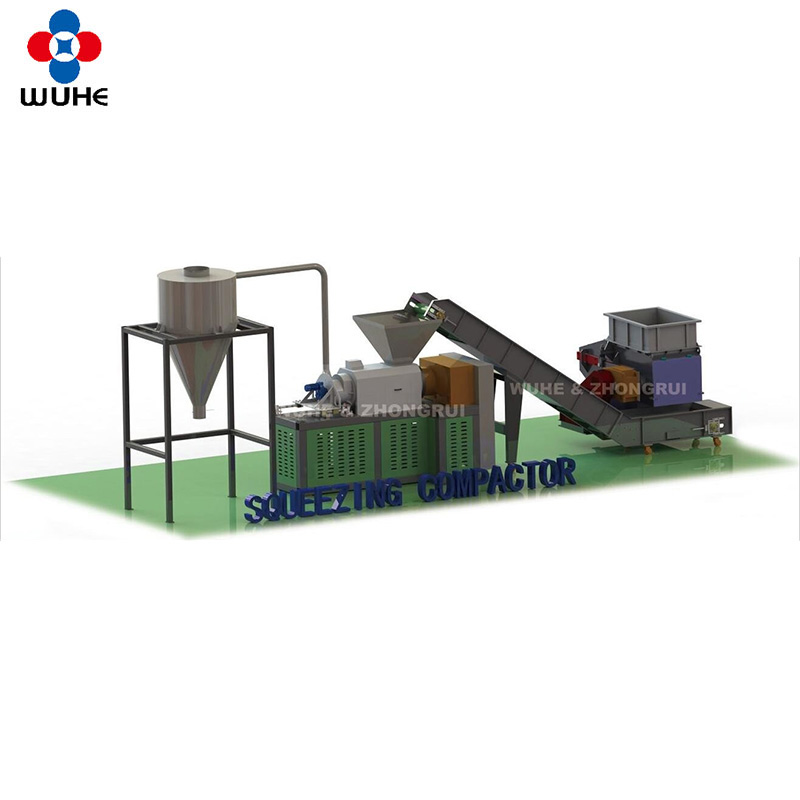

Squeezer compactor machine

● The equipment is suitable for washed films, PP woven bags and so on, There is no requirement for the moisture, this machine can connecting with floating washer directly.

● The equipment adopts screw extrusion principle, then discharge the water out from the materials. It will has a strong friction in the processing of extrusion. The materials will heated after friction, then the materials will in a semi plasticizing state. After the cutting system, the materials will transported to the silo by air sending, The materials can be easy packed under the silo or processing it to granules again.

● If you used Squeezing compactor, this machine can instead of following three machines. Dewatering machine, dryer and a Agglomerator. High efficiency and low consumption is also it's features.

Electrical control system

● PLC automatic control

● Final product