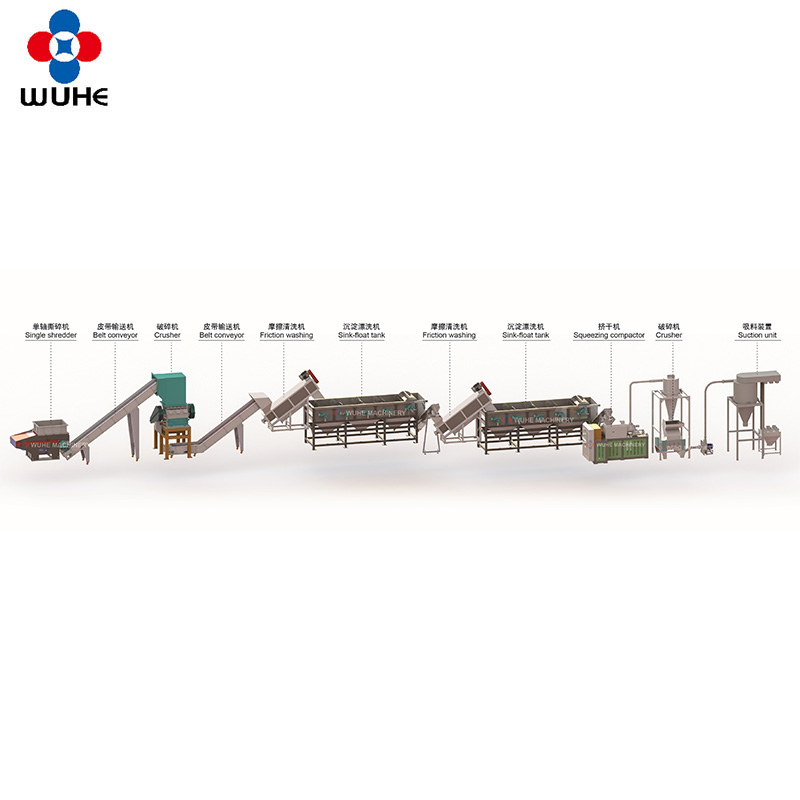

PET bottles recycling washing production line

Main parameter

Belt conveyor

● Function: rubber belt conveying the bottles to the next process.

Bale opener

●Function: Break the PET bale

Roller filter

● Function: to separate the rocks or sand from the bottles.

Label remover

● Function: remove the labels from bottles (80-90%).

Pre-washer device

● Function: wash the surface sands and other dirty.

Sorting platform&Metal detector

● Function: manual sorting the metal or other dirty from the bottles.

PET bottle Crusher machine

● Crusher has two types different from materials, such as dry and wet type.

● The fixed knife is fixed on the rack. And changing the tool and the network uses the hydraulic pressure support.

● It is suitable for PE/PP and PET broken.

● This machine adopts the steel structure, casting steel frame, steel cutting tools, which avoids splitting.

● Using ladder type cutter can improve the shearing force and increase crushing efficiency.

● Using movable sieve can conveniently assemble and disassemble and conveniently clean and change network.

● Feeding door uses insulation sandwich to reduce noise and improve the working environment.

● The feeding hopper adopts protection switch to protect the safety of operating person.

High speed friction washer machine

● Separated spiral screw keeps flakes from going out immediately but rotating on a high-speed basis. Therefore mutual strong frictions between flakes and flakes, flakes and screw can separate flakes from dirty things. The dirty will be discharged from sieve holes.

Screw loader machine

● Function: using screw conveying the flakes to the next process.

Floating washer machine

● Function: Wash the PET flakes in water tank to separate the PP or PE material. (PP/PE on water, PET sink at bottom).

Hot washer machine

● Function: Use steam and soda and other cleaning agents to better clean the oil stain or other adhesive impurities on the surface of bottle flakes.

Dehydrator machine

● Part in contact with materials of WH series centrifugal dryer is made of stainless steel to keep conveyed materials from pollution. Full automatic design needs no adjustment during operation.

● Principle: Materials are conveyed into centrifugal dryer by spiral loader.

● Separated spiral screw keeps flakes from going out immediately but rotating spirally on a high-speed basis. Therefore centrifugal force can separate water from materials. The materials will be discharged from sieve holes.

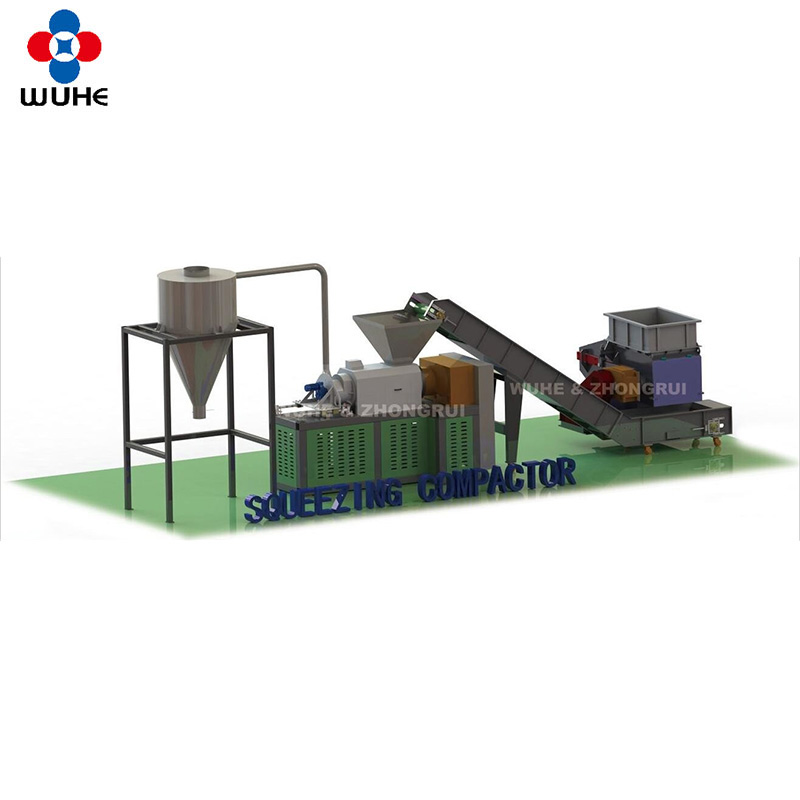

Dryer machine& air-sending machine

● Function: Use a fan to dry the bottle flakes from the dehydrator with dry air to achieve further drying.

Labels Sorting machine

● Function: to separate the labels pieces from the clean PET flakes.

Double position Bag filling machine

● Function: double position bag filling system is optional for your flakes storage.

Electrical control system

● PLC automatic control