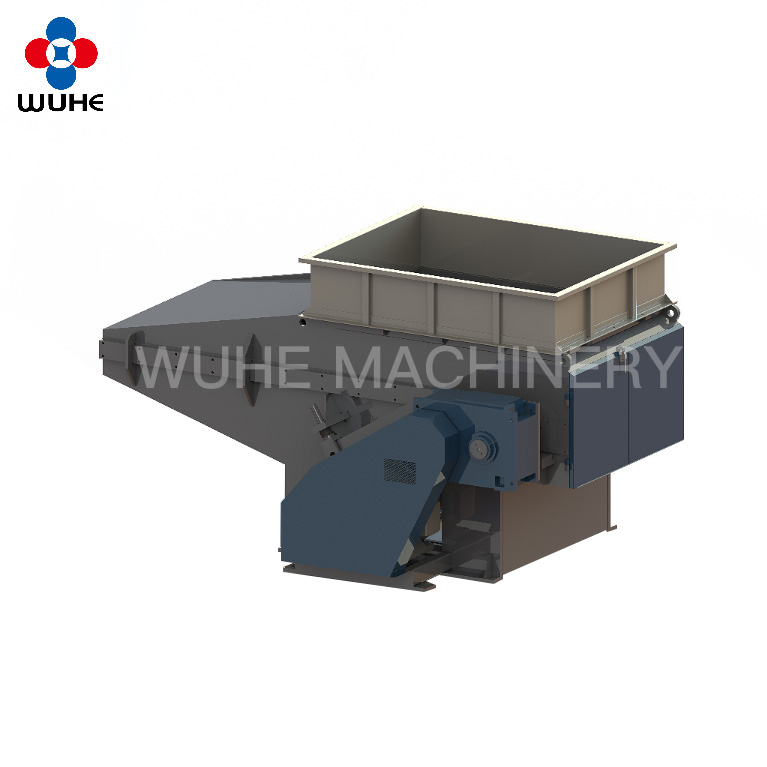

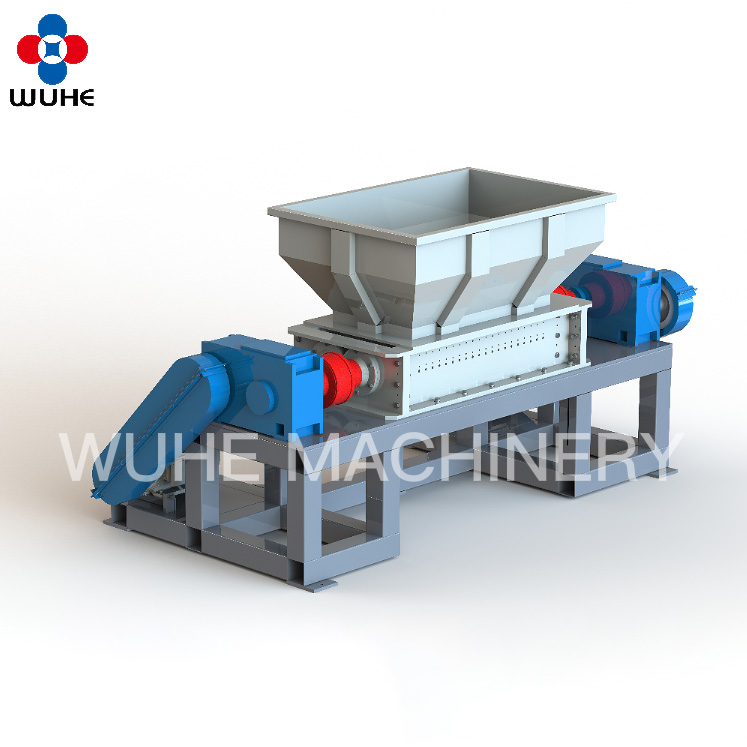

Single Shaft Shredder

Main parameter

|

Model |

Motor Power(Kw) |

Hydraulic Power(Kw) |

Rotating Diameter(MM) |

Fixed Knife |

Rotating Knife |

Remark |

|

DS-600 |

15-22 |

1.5 |

300 |

1-2 |

22 |

Push |

|

DS-800 |

30-37 |

1.5 |

400 |

2-4 |

30 |

Push |

|

DS-1000 |

45-55 |

1.5-2.2 |

400 |

2-4 |

38 |

Push |

|

DS-1200 |

55-75 |

2.2-3 |

400 |

2-4 |

46 |

Push |

|

DS-1500 |

45*2 |

2.2-4 |

400 |

2-4 |

58 |

Pendulum |

|

DS-2000 |

55*2 |

5.5 |

470 |

10 |

114 |

Pendulum |

|

DS-2500 |

75*2 |

5.5 |

470 |

10 |

144 |

Pendulum |

Machine details

Feeding hopper

● Special designed feeding hopper to avoid material splashing.

● Suitable for conveyor, forklift and travelling crane to feed material.

● Satisfy special requirement to make sure the feeding continuity.

Rack

● Special shape design, high strength, easy maintenance.

● CNC process.

● Distressing heat treatment.

● Orbit design for pusher, flexible and durable.

● Body material: 16Mn.

Pusher

● Special case shape design, high strength, easy maintenance

● CNC process

● Roller support, location, flexible and durable

● Material: 16Mn

Rotor

● Cutter optimization arrangement

● Row cutter precision <0.05mm

● Tempering and distressing heat treatment

● CNC process

● Blade material: SKD-11

● Special design for knife holder

Rotor bearing

● Embedded bearing pedestal

● CNC process

● High precision , stable operation

Mesh

● Consists of mesh and mesh tray

● The mesh size should be designed according to different material

● CNC process

● Mesh material: 16Mn

● Mesh tray hinge type connection

Hydraulic system

● Pressure, flow adjustment

● Pressure, flow monitoring

● Water cooling

Drive

● SBP belt high efficient drive

● High torque, hard surface gearbox Control

● PLC automatic control